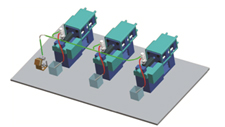

Hot Air Dryer

Hopper Capacity from 30 Litres to 4000 Litres

Available in Machine mounted or Floor mounted versions

Salient features of Toshiba Machine Hot Air Dryer:

Energy efficient

Compact and light weight

Fully insulated aluminium bin with SS cladding

PID control of temperatures

Large cleaning window for quick material change over from 60 Liter onwards

Optional features:

Pneumatic Suction box for line purging

Special discharge outlets for various injection molding machines and Extruders